NORTHWEST MACHINING AND MANUFACTURING OFFERS A FULL LINE OF MANUFACTURING SERVICES SPECIALIZING IN PRECISION MACHINED COMPONENTS AN9D ASSEMBLIES

Welcome To Northwest Machining & Manufacturing

Northwest Machining & Mfg., Inc. (Northwest Machining) is a contract manufacturer of precision machined components and assemblies. Northwest Machining’s capabilities are among the largest and most advanced in Idaho. We can machine simple components to complex machined assemblies. Our aim is to be the machining vendor of choice for our current customers and to use our extensive experience to develop new business relationships.

The employees of Northwest Machining are committed to meeting the requirements of our customers and applicable government, statutory/regulatory agencies. As a means to meet these requirements, we document our best business practices, and foster an environment of continual improvement within our organization. Northwest Machining has established and maintains a quality management system in accordance with SAE AS9100D and ISO9001:2015.

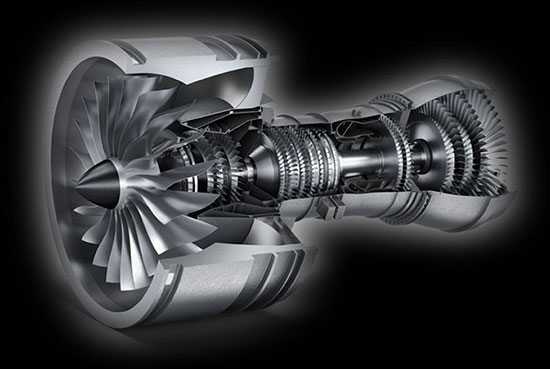

CNC MILLING

Our specialized milling process enables us to manufature parts with intricate geometry and detail while maintaining high precision and accuracy

CNC TURNING

Northwest Machining & Manufacturing, Inc. specializes in high precision CNC and manual turning. Our current turning capacity is up to 58 inches in diameter

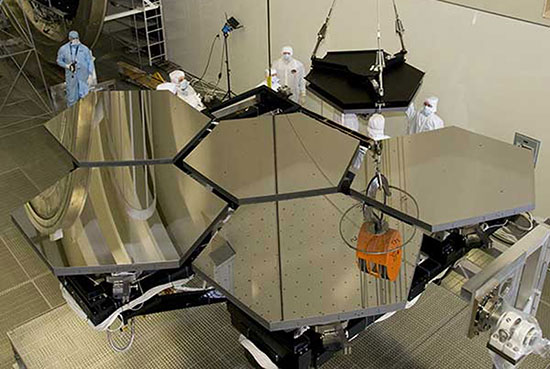

MANUFACTURING & ASSEMBLY

Using a network of vendors we are able to expand our manufacturing and processing capabilities. We are certified to ISO9001:2015 and AS9100D quality standards

SUPPLY CHAIN SERVICES

From material procurement and production to securing limited availability resources, Northwest Machining & Mfg., Inc. offers complete supply chain management services

ISO9001:2015 & AS9100D Certified

The Team at Northwest Machining & Manufacturing takes quality very seriously. Our Quality Management System ensures you receive the highest quality product, on time, and within budget. Our well documented procedures result in consistent output, with greatly reduced defect rates. We seek customer feedback, and have adjusted our goals and objectives as a company based on this information.